Products

Smoke Machines

Hazers

Specialist

Smoke Fluid

Special Effects

By Application

Sales

How to order

Q & A Info

About us

Who we are

Contact

Your Basket

|

|

|

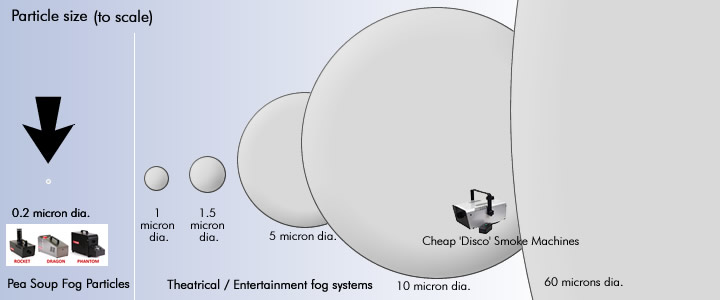

Smoke Particle Size - why smaller is better!

Common to this range of smoke generators is our incorporation

of precision, machined, specially treated steel heat exchanger blocks

in which the smoke chemical is vaporised.

Conventional smoke generators normally use either

cast or platen type aluminium heat exchangers, which whilst very

cost effective to make, generally produce a smoke particle with

a mass median diameter (mmd) of 1 - 10 microns.

This compares with a typical particle size of just

0.2 - 0.3 micron mmd for our smoke systems below, be they water

or oil based.

The general benefits of producing such a consistent

and clearly defined particle distribution are:

- the smaller the particle size of the smoke, (or

more accurately fog) the smaller the amount of chemical is required

within the atmosphere to achieve any given visibility. This can

have a significant effect on running costs for heavy users of

artificial smoke (fire brigades etc.)

- the less the amount of chemical in the atmosphere,

the safer the smoke if measured in terms of relative Occupational

Exposure Levels.

- the smaller the particle size of the smoke,

the lower its settling velocity (the rate at which a particle

will fall, due to gravity). A smoke particle of unit density,

0.2 micron in diameter, will fall at 8mm/hour,

compared to a 2 micron particle, which falls at 468mm/hour. In essence

this means that the smaller the particle of smoke you produce,

the less chance there is that deposition of smoke particles will

occur on surfaces.

Small particle size = no residue!

Size of fog particle

[diameter in microns / µm] |

Setting Velocity due to gravity (millimetres

per hour) |

|

0.2

|

8.14 |

Typical Pea Soup smoke system

particle |

| |

So, in 2 hours (the average hang time), a Pea

Soup smoke particle will only have fallen 1.6cm. |

|

|

125.28 |

Typical

particle size for a cast heat exchanger block [virtually all

'theatrical / entertainment' smoke machines] |

| 2 |

468.00 |

| 3 |

1,026.00 |

| 4 |

1,800.00 |

| 5 |

2,793.60 |

| 6 |

3,996.00 [4 metres] |

Manufacturers'

quoted particle size of cast heater blocks when pumping smoke

at high output (wet smoke) |

| 8 |

7,056.00 [7.05 metres] |

| 10 |

11,016.00 [11 metres] |

| 20 |

43,560.00 [43.5 metres] |

| 30 |

97,920.00 [97.9 metres] |

An artificial smoke particle increases rapidly with

particle size. The settling velocity is proportional to the square

of the particles diameter.

The terminal settling velocity of an aerosol or "artificial

smoke" particle increases rapidly with particle size. The settling

velocity is proportional to the square of the particle diameter,

although sub micron particles, such as those produced by Pea Soup

branded smoke systems require the use of slip correction factors.

Calculated for standard density spheres

at 293 K [20° C] and 101 kPa (1 atm).

"Aerosol Technology", William C. Hinds, Wiley-Interscience,

1999

|

Rocket

Hand Portable Smoke Machine - hand-portable unit.

Can deliver quick dispersing smoke (PS21) or long lasting (PS23).

Off-power facility. 240/110v. |

|

Dragon

2.2kW High Output Smoke Generator - continuous

high output 2.2kW machine with a choice of fluids available

for either quick dispersing smoke or persistent. 240/110v. |

|

Oil Based Smoke Generator - oil-based smoke machines

with continuous highly controllable output. The generated smoke

can withstand high temperatures, is very persistent and has

a very small particle size (no residue) and can easily be ducted.

240/110v. |

The Oil Based Smoke

Generator in operation

|